John Crane Diamond® Unique Characteristics Extend Mechanical Seal Life

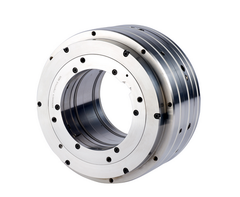

Derived from nature’s hardest substance, John Crane Diamond uses ultrananocrystalline diamond (John Crane Diamond®) treatment—a thin film of genuine diamond that is grown via chemical vapor deposition on the seal face. Only John Crane integrates this technology directly into our manufacturing process, bringing you unmatched expertise in seal and face treatments with best-in-class adhesion.

John Crane Diamond is available on sintered silicon carbide and tungsten carbide substrates offering performance benefits in a wide range of applications in nearly every industry. For a full list of seal and material availability click here.

John Crane Diamond for Industrial Applications

Adding John Crane Diamond to mechanical seal faces helps overcome short seal life and equipment breakdowns caused by harsh operating conditions, including:

- Abrasive particles

- Low lubricity

- Intermittent dry running

Meet Environmental Objectives

Due to its low coefficient of friction, John Crane Diamond generates less heat, reducing the need for cooling water and, in some cases, auxiliary cooling equipment. In instances where auxiliary equipment is required, the reduction in heat generation can significantly reduce the size of the heat exchanger or sealant system, resulting in decreased water consumption and lower equipment costs.

The face treatment’s low friction also reduces energy loss. Depending on conditions, reducing the motor’s power consumption alone can result in a payback period of fewer than 12 months. This decrease in operating costs continues throughout the life of a seal.

Achieve your environmental goals through:

- Less water consumption

- Reduced energy usage

- Lower operating costs

Benefits

- Increased durability: The film of pure diamond delivers unmatched hardness, superior chemical stability and a low coefficient of friction. Seals are more durable, with increased longevity.

- Increased reliability: Rigorous controls assure film crystallinity, thickness, consistency and bonding that enhance seal life as well as poor lubricating capabilities, extending MTBF.

- Increased productivity: Mission-critical equipment stays up and running, helping you achieve production goals.

- Reduced costs: Diamond face treatments provide a lower coefficient of friction. This results in cooler running faces, reduced power consumption, increased reliability and lower lifecycle costs.

High-quality and low-maintenance SOLAS/MED approved liferaft solution for automatic or manual throw overboard launch from vessels of all types.

- High durability with an expected lifespan of 15-20 years

- Can be deployed at temperatures as low as -30 °C

- Holds several flag state approvals

- Two individual buoyancy chambers, each carrying capacity weight

- Sizes: 4, 6, 8, 10, 12, 16, 20, 25 and 35 persons

- Exceptionally stable even in rough seas

Product Availability

John Crane Diamond® treated silicon carbide offers performance benefits for a wide range of applications in nearly every industry. Seal face treatments are available as an enhancement to many of our most widely used seal families, such as:

- Type 5600 Universal Cartridge Seal Family

- Type 5800 Slurry Seal Family

- Type 48VBF Boiler Feed Water Seal

- Other High-Performance Sealing Solutions

John Crane Diamond is also offered on tungsten carbide for select applications, including Type 8AB seals used on high-speed, integrally geared pumps where a clamped-in tungsten carbide substrate is often required.

Applying John Crane Diamond combines tungsten carbide’s unique mechanical properties with diamond’s seal face tribological properties, and provides a quick and easy drop-in solution to address failures associated with high heat generation, poor lubrication, frequent starts and stops, and challenging start-up conditions.

John Crane Diamond on tungsten carbide is available on Type 8AB mechanical seals